Custom Printed Polyester Fabric

- Custom printed polyester fabric: High resolution, flexibility and fine patterns.

- Low cost,Less waste: Fast sampling and short-term delivery allows you to order as much or as little as you need without having to worry about excess costs.

- Unlimited repeat size: You can order as many samples as you need without worrying about running out of fabric or wasting any money.

- Fine patterns and a high degree of flexibility make it the perfect choice for unique printing needs

Choose The Pattern Of Printed Fabric You Want

Custom printed polyester fabric is perfect for businesses who need a high resolution print with flexibility and fine patterns. Fine patterns and a high degree of flexibility make it the perfect choice for unique printing needs, while its resistance to wrinkles makes it ideal for use in apparel, drapery, or other items that require stretchability. Plus, our printers are able to handle even the most intricate designs with ease. Contact us today to learn more about this versatile fabric!

In addition to custom printed polyester fabrics, we can also provide embossed polyester fabrics, jacquard polyester fabrics, satin polyester fabrics and related bedding and home textiles.

If you don’t find the printed fabric you need, you can send us a custom request.

Cxdqtex-Your Best Choice For Printed Fabric Suppliers

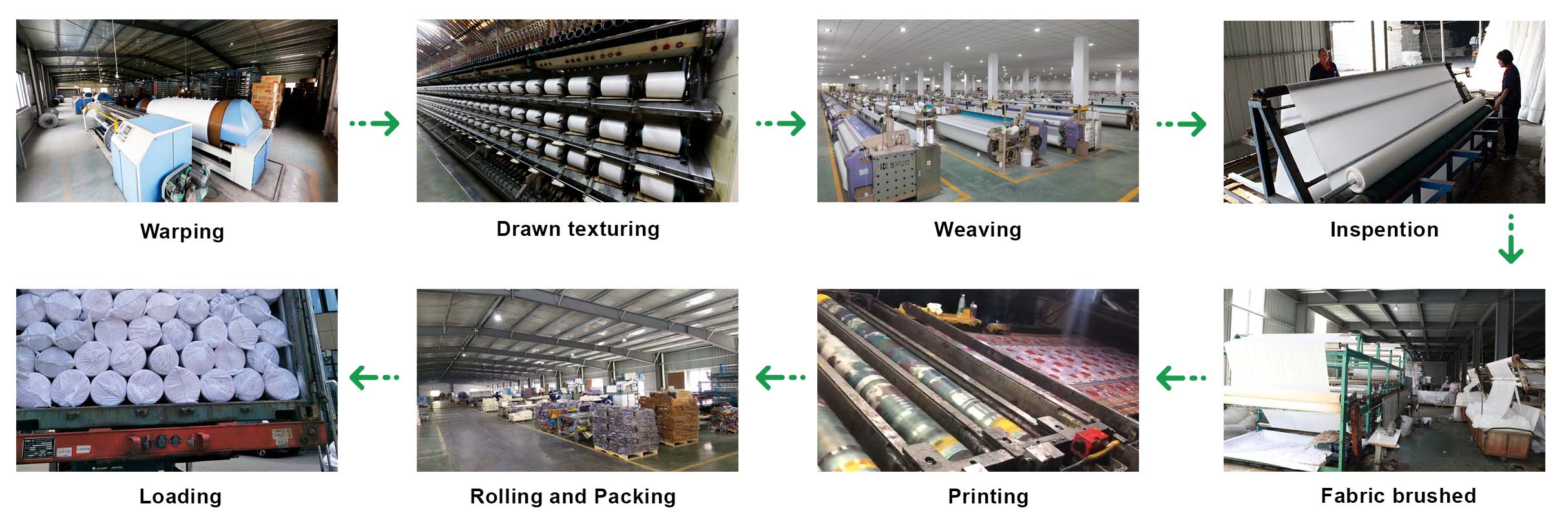

It was established in 2009 and covered an area of 3,700 square meters. We have nearly 500 sets of equipment for fabric production and 200+ professional technicians. We have the strength and confidence to provide cost-effective and high-quality printed fabric to customers around the world and are committed to becoming a leading fabric expert and supplier in China. With high-quality products and a perfect service system, we have provided solutions for hundreds of customers around the world.

Core competence

Order printed fabric at Cxdqtex and you will also get the following benefits:

Aprofessinoal Workteam

We always appreciate it when our customers are satisfied with the quality of our products. Our QC team is responsible for ensuring that every step in the manufacturing process - from the raw materials to packing - meets high standards. They will check everything from the ingredients and labeling to production procedures and final product quality.

Professional Sales

We are confident that we can provide the best possible experience to our customers. Our durable quality and good reputation have been built through years of hard work and dedication by our team. We hope that you will choose us as your preferred provider in the future.

Professional Certification

We are glad to share that we have more than ten years of fabric production process and rich production experience. Our products have passed Oeko-tex certification, which is the global standard for environmental and human health protection. Additionally, our products are ISO9001 and ISO14001 certified, in order to meet the highest international quality standards.

Professional Equipment

We have 485 sets of 190T-320T size water-jet looms and jacquard machines,6 sets of HONGYUAN texturing machines, 6 sets of beam warping machines,2sets of brushed machines, 2 sets of ultrasonic machines.

Custom Printed Polyester Fabric Service

As your most trusted and professional printed fabric manufacturer in China. We provide customers with professional customized services. We welcome all customers to customize printed fabrics.

In order to meet the different needs of customers, in order to make your products stand out, we provide you with customized services. Our team will provide you with professional solutions, and you can also communicate with our design team to produce the perfect printed fabric together to enhance the added value and brand image of your products.

Fabric FAQ Guide

We are the direct manufacturer with more than 20 years experiences in polyester microfiber fabric and wax fabric. (like pigment printed , disperse printed , dyed fbaric .ect.)

Sample order is acceptable. Please contact with us and make sure what sample you need, in general,It will take 7-15 days to finish your sample.

In general, the leading time is about 15 to 35 days after receive the deposit , But please confirm the exact delivery time with us as different products and different quantity will have different leading time.

We need 30%T/T for deposit when you place the order ,the balance should be paid against B/L copy within 15 days.We can accept LC at sight. D/P at sight, CAD.

Our sales service is 24 hours , if you have any question, pls free contact with us .

1-Ask your agent in China to check the goods for you.

2- Ask we send you the shipment sample for confirmation before ship. Also we can send you 1 meter.

Printed Fabric FAQ Guide

1. If you need printed home textile fabrics, which printed fabric can you choose?

Pigment printing, dispersion printing, flat screen printing, paper printing, transfer printing.

If you are doing business with printed fabrics, then you should choose proper printing fabrics as per your need and requirement. Here, we would like to recommend to you some popular printed fabrics name like –

Pigment printing – This is one of the cheapest printing processes. It provides you maximum output always. It offers high printing speed and quick sampling as well. The main benefits of pigment printing are that the procedures can be done without any subsequent washes. For photo printing, this type of printing is the top end but for the home fabricated process you can use some other option as well.

Dispersion printing – This is another common type of fabric ink and this is called disperse the ink. This is used for the dye-sublimation printing process as well. It becomes a popular part of the textile industry. This type of inks has different parts like medium energy, low energy, and high energy as well. Low energy dye dispersion is mainly used for transferring paper to any other fabric as well. It uses to generate pressure and heat.

Flat Screen Printing -This is another popular fabric that you may use for your textile industry. Here, you will find a different pattern and you have to choose the best pattern as per your need and requirement. You can reproduce using this fabric several times. Here, you will find a different pattern for each color. There are different types of machines available for printing.

Paper printing – This is another best fabric and common as well. You can use this for your textile business. There are different types of paper printings available in the market and you may choose anyone as per your need and requirement.

Transfer printing – This is another best term related to printing textiles. This is one type of fabric which helps to print pottery. In this process, printing must be done on a flexible nontextile subtract and then transfer to the real textile process.

2. What should I pay attention to when producing Printed Fabric?

Pay attention to the size of the pattern, the color of the pattern, the feel of the fabric, the vividness of the color and the color fastness.

If you will choose the printed fabric business, then there are several factors you have to remember. First, you have to check the proper pattern. Pay always attention to the pattern and size of the pattern as well. Second is, the color of the pattern. This is very important. Color is also very important. The more colorful design and pattern you will choose the more attractive the textile product you will be able to produce.

3. What size pictures does Printed Fabric accept?

A flower circumference of 64CM, width of the width 150CM-280CM

If you want to print different types of pictures then first you should know the size of the picture. Every machine has some limitations and they have proper size as well. If you want to printed flower circumferences of 64 CM then the width will be 150 CM to 280 CM.

4. How should the printed fabric be stored?

Dry, cool, ventilated, no longer exposed to the sun,

You have to store it properly so that it will never damage. Once you are done rolling in the factory, you have to store in a place that is well ventilated. You have to keep those rolling in a place where sunlight will not come. And you have to keep then in a place where dust will not come. There are some dresses where flat storage will not work properly. It never works because it will bring creases on new clothes.

5. How about the quality service of Printed Fabric?

After the container is shipped from the factory to 6 months after the customer receives the container.

If you will choose us, we will always ready to provide the best quality product at the best time. You can check our process to know more details. Once you place the order, after ready material, we will ship the container. Within 6 months probably customer will get the products as well.

6. How long does the production cycle of Printed Fabric take?

If the quantity is 1*20ft, about 25-30 days after receiving the deposit,

If the quantity is 1*40HQ, about 35-40 days after receiving the deposit.

The printed fabric is checked according to the number of clients. If they will get 1*20ft, then once you make a deposit, after receiving the deposit, it takes 25 to 30 days. And if they get 1*40 HQ, then after receiving the deposit; they will take 35 to 40 days for production.

7. What is the starting volume of Printed Fabric?

Factory pattern minimum order quantity, MOQ: 5000M/DES, each pattern

The customer’s pattern minimum order quantity, MOQ:15000M/DES, and 5000 meters for each pattern.

For each pattern, you have to place a minimum order quantity that is MOQ – 5000M/DES and if you need a custom pattern, then you will take minimum order quantity MOQ: 15000M/DES and more 5000 meters for every pattern.

8. What are the packaging methods for printed fabrics?

Single-width roll or double-width roll with paper tube, covered with plastic bag

Packed in a woven bag,

For printing fabrics properly, you have to follow proper methods. There are different types of printing fabrics available in the market and you have to choose the best one. It’s always true that packaging is very important and it plays an important role as well.

There are different types of packaging options available and you may choose anyone as per your need and requirement. For the printed fabric industry, there are different types of packaging solutions available and you just need to choose the best one. You will find from market paperboard boxes, corrugated boxes, Plastic boxes, rigid boxes, Chipboard packaging, Polybags, and Foil sealed bags.

As per your material type you have to choose the best packaging mode. As per your budget and import destination or shipping destination, you have to choose the proper packaging method as well. For narrow distance shipping, paperboard is the best but for a long journey, you have to choose some rigid box as well.

9. How fast is the printed fabric?

Beach pants – Yes, this is another attractive man and women garments. Most of the people who want to enjoy a beach party prefer this fabric. They prefer it because it’s attractive. You have to use different colors and a single pattern to make this type of textile.

Softcover fabric – You can make different types of softcover for different purposes like a chair, table, sofa, caution, gloves, etc. The different color full design makes that entire product attractive. The market demand for such products is also very high.

Ice silk mat – This is another best one. The ice silk mat is very beautiful and it looks attractive. In the market, you will find an attractive design on printed products. The demand for this kind of product is increasing day by day. So, you can choose this type of print as well.

Wax cloth fabric – This is another best cloth fabric available that provides you good business. Choose a different pattern and then start producing. The market demand for this item is also high. Choose the best fabric as per your need and requirement. Find the best deal now!

The color fastness of pigment printing is average, and the color fastness of dispersion printing is very good.

Mainly, there are a few categories where you will use printed fabric to make good clothes, like

10. What are the main application areas of Printed Fabric?

Sheet fabric, beach pants, sofa cover fabric, ice silk mat, wax cloth fabric.

There are different types of printed fabric available. You may choose anyone as per your need and requirement…

Flat Screen Printing -This is another popular fabric that you may use for your textile industry. Here, you will find a different pattern and you have to choose the best pattern as per your need and requirement. You can reproduce using this fabric several times. Here, you will find a different pattern for each color. There are different types of machines available for printing.

Pigment printing – This is one of the cheapest printing processes. It provides you maximum output always. It offers high printing speed and quick sampling as well. The main benefits of pigment printing are that the procedures can be done without any subsequent washes. For photo printing, this type of printing is the top end but for the home fabricated process you can use some other option as well.

Dispersion printing – This is another common type of fabric ink and this is called disperse the ink. This is used for the dye-sublimation printing process as well. It becomes a popular part of the textile industry. This type of inks has different parts like medium energy, low energy, and high energy as well. Low energy dye dispersion is mainly used for transferring paper to any other fabric as well. It uses to generate pressure and heat.

Transfer printing – This is another best term related to printing textiles. This is one type of fabric which helps to print pottery. In this process, printing must be done on a flexible nontextile subtract and then transfer to the real textile process.

Paper printing – This is another best fabric and common as well. You can use this for your textile business. There are different types of paper printings available in the market and you may choose anyone as per your need and requirement.

Choose the best one as per your need and requirement. All items are highly demanding and you may buy from online as well.

11. What types of Printed Fabric are there?

Pigment printing, dispersion printing, flat screen printing, paper printing, transfer printing

There are different types of printed fabric available. You may choose anyone as per your need and requirement…

Flat Screen Printing -This is another popular fabric that you may use for your textile industry. Here, you will find a different pattern and you have to choose the best pattern as per your need and requirement. You can reproduce using this fabric several times. Here, you will find a different pattern for each color. There are different types of machines available for printing.

Pigment printing – This is one of the cheapest printing processes. It provides you maximum output always. It offers high printing speed and quick sampling as well. The main benefits of pigment printing are that the procedures can be done without any subsequent washes. For photo printing, this type of printing is the top end but for the home fabricated process you can use some other option as well.

Dispersion printing – This is another common type of fabric ink and this is called disperse the ink. This is used for the dye-sublimation printing process as well. It becomes a popular part of the textile industry. This type of inks has different parts like medium energy, low energy, and high energy as well. Low energy dye dispersion is mainly used for transferring paper to any other fabric as well. It uses to generate pressure and heat.

Transfer printing – This is another best term related to printing textiles. This is one type of fabric which helps to print pottery. In this process, printing must be done on a flexible nontextile subtract and then transfer to the real textile process.

Paper printing – This is another best fabric and common as well. You can use this for your textile business. There are different types of paper printings available in the market and you may choose anyone as per your need and requirement.

Choose the best one as per your need and requirement. All items are highly demanding and you may buy from online as well.

12. How to choose the Printed Fabric you need?

You can choose the pattern of the factory, you can also use the customer’s pattern drawing, making nets.

13. What patterns can be printed on Printed fabric?

Cartoon animal flower pattern, big flower style flower pattern, geometric figures,

There are different types of patterns available in the market and you may choose any one pattern which suits. You have to do the market analysis properly to choose the best-printed fabric as well. You may choose a big flower style, cartoon animal flower pattern, and geometric figure as well.

14. How to print according to the printed fabric provided by the customer?

First, the customer provides the pattern drawing, and after the drawing is sent to the customer for confirmation, after confirmation, the screen can be made according to the customer’s drawing, and finally the production of printing is arranged for the bulk.

Sometimes, the customer will provide you print and you have to print as per their design. You have to set up a proper pattern, block to print customers’ designs as well. There are some processes you have to follow to do that!

15. If the customer uses the customer's pattern, how to calculate the cost?

The cost is calculated by arranging the color registration of the customer pattern.

Once you start a business in the textile, you will find different types of customers. Some will choose your fabric and design some will offer you their design and pattern as well. Now, if they will choose your design then you can easily choose cost but if they will provide you their design, then how you will calculate the cost? Do you have any idea? Well, if you are new in this business, then learn here now!